ELECTRO-HYDRAULIC CNC

PRESS BRAKE

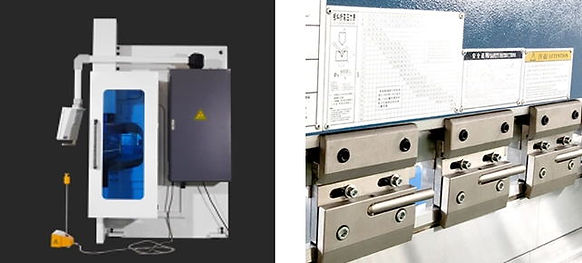

ELECTRO-HYDRAULIC CNC PRESS BRAKE

About The Press Break

MACHINE

•Multiful Core Technologies

•Safety Standard is a must

•High Quality Parts

Core Technologies

•Controller controls and adjusts Y-axis and X-axis

•Servo drive and control positioning of X-axis and Y-axis

•Adopting HIWIN ball screw and linear guide rail, accuracy 0.05mm

•Front supporter bracket

•Germany Bosch Rexroth hydraulic valve block

•Germany EMB oil tube connector

•Germany Siemens main motor

•France Schneider electrics

•Hydraulic & electrical overload protection

Top and bottom dies

(86 °, R0.6mm, material: 42CrMo HRC ±47 °)

•Ajdust quality stop finger

•Increase axis support 4+1 axis (R axis )

.jpg)

Safety Standard

1.EN 8622:2009 + A1:2013 2.EN ISO 8100:2010 3.EN 60204-1:2006+A1:2009

Discover high-quality parts for XT laser machines that meet industry standards for performance and durability. Upgrade your equipment for enhanced efficiency and precision in your projects. Trust us to keep your XT laser running at best!

STOP FINGERS

MOTORIZED CROWN SYSTEM

FRONT SUPPORTS

ELECTRIC CABINET

Application

XT brand press brakes are not only suitable for the industry of heavy-duty

machinery,locomotive,aviation,shipbuilding,but also satisfied the tube&lamp pole production via using some

assistant equipment of uncoiling,flattening,closing up and welding.

-

MAX BENDING FORCE

-

MAX BENDING LENGTH

-

COLUMN DISTANCE

-

THROAT DEPTH

-

RAM STROKE

-

CLOSED HEIGHT

-

APPROACHING SPEED

-

WORKING SPEED

-

RETURN SPEED

-

MAIN MOTOR POWER

-

CNC SYSTEM

-

OIL TANK CAPACITY

-

2250KN

-

3100mm

-

2700mm

-

410mm

-

215mm

-

480mm

-

160mm/s

-

10mm/s

-

140mm/s

-

22Kw

-

Holland Delem DA66T /DA53T/TJS CNC system controlling Y1、Y2、X axes and hydraulic crowning.

-

400L

-

X axis Accuracy

-

Stroke

-

Speed

-

Power

-

X axis Accuracy

-

Stroke

-

Speed

-

Power

-

Length

-

Width

-

Height

-

±0.10mm

-

500mm

-

400mm/s

-

1Kw

-

±0.10mm

-

200mm

-

200mm/s

-

1Kw

-

3980mm

-

22Kw

-

1960mm

-

2650mm